Description

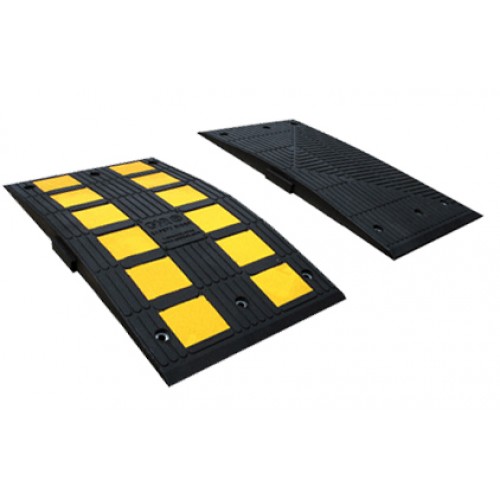

The Safety Rider® rubber mini hump is a unique modular traffic calming device designed to slow traffic while maintaining a continuous traffic flow. The mini hump is constructed of interlocking units with a tongue and groove system. This allows the humps to be linked together to cover the width of any roadway. End caps are available to provide a smooth finish to the ends of the hump.

Features

The Safety Rider® is constructed from 100% recycled tires. Unlike asphalt humps, our mini humps are preformed for a uniform and consistent profile and a smooth, safe ride. The mini humps are simple to install and do not require road closures. Plastic shields are inserted into pre-drilled holes and the units are bolted down to keep from shifting. The Safety Rider® can be easily removed for storage or relocation.

Mini speed humps are ideal for slowing traffic in school parking lots and crossings, playground areas, hospitals, parking facilities, and anywhere a slow traffic flow is required. Heavy load bearing truck traffic is ideally facilitated by the Safety Rider® mini hump.

Molded highly reflective tape provides optimal visibility even on a dark night, alerting drivers well in advance.

Safety Rider® mini humps are covered by a 3 year warranty; 1 year on the tape (under normal use).

Reviews

There are no reviews yet.